CNC machines present only one demand at the highest level. Stability. If you are cutting metal, engraving wood, or doing precision manufacturing, even a small system delay can definitely spoil your work. That’s the main reason why experts are ditching Windows and going to CNC for Linux.

Linux is mind your own business, and totally reliable for real-time control. There are no interruptions due to updates. No background bloat. No random restarts. Just pure performance. That’s why Linux for CNC is the best choice in workshops, factories, and maker labs.

Another huge reason is price. Most CNC software for Linux is open-source and free. You have industrial-grade control without spending money on licenses. LinuxCNC, for instance, gives you full machine control, customization, and real-time precision that Windows setups often have to compromise.

But quite a few beginners still wonder:

- Which Linux works best for CNC?

- How do I install LinuxCNC?

- Can Linux CNC run on Windows?

- How to add the repo for Linux CNC?

This article explains everything so clearly and in a very practical way. No fluff. Just steps that work.

Let’s set up your CNC system properly.

Get exclusive access to all things tech-savvy, and be the first to receive

the latest updates directly in your inbox.

What is CNC for Linux?

CNC for Linux refers to the use of a Linux operating system in conjunction with CNC control software for controlling machines such as mills, cutters, engravers, or drills. It is mainly done to achieve greater stability and real-time performance.

Windows-based controllers are being replaced by Linux, the latter:

- controls motors

- executes G-code

- controls stepper drivers

- handles machine automation

- gives precision timing

Linux offers closer control of hardware, which is necessary for machining.

Why Use Linux for CNC Instead of Windows?

Linux for CNC has become the favorite choice because it incorporates features like real-time kernel support, reduced latency, and enhanced stability during long machine operations. As a result, it avoids crashes and timing mistakes.

The main advantages:

- real-time performance

- no forced updates

- fewer system freezes

- Low resource usage

- free and open-source

- better hardware compatibility

If it is a matter of time delay, a 1-second lag can be very detrimental in CNC work. The probability of such a situation is minimized by Linux.

What is LinuxCNC?

LinuxCNC, the most widely used open-source CNC control software for Linux, interprets G-code into machine movements at a very detailed level. It can even directly control motors and drivers.

Besides, it supports:

- milling machines

- lathes

- routers

- plasma cutters

- 3D printers

- robotics

It’s basically the brain of your CNC machine.

How to Install LinuxCNC?

Installing LinuxCNC is easy using official repositories. You simply add the repo for Linux CNC and install packages using apt.

Step 1: Add repo for Linux CNC

sudo add-apt-repository ppa:linuxcnc-dev/linuxcnc

Step 2: Update system

sudo apt update

Step 3: Install LinuxCNC

sudo apt install linuxcnc-uspace

output

LinuxCNC installed successfully

Now launch:

linuxcnc

You’re ready to configure your machine.

How Does LinuxCNC Actually Work?

LinuxCNC reads G-code files and translates them into real-time electrical signals that move stepper or servo motors accurately.

Basic flow:

- Load G-code

- Software processes commands

- Signals sent to drivers

- Motors move the machine

Example G-code:

G21

G90

G1 X10 Y10 F100

Output:

Machine moves 10mm in X and Y direction.

This precision is why Linux is trusted.

Popular CNC Softwares for Linux

| Software | Purpose | Best For |

|---|---|---|

| LinuxCNC | Machine control | Full CNC control |

| FreeCAD | CAD modeling | Design parts |

| bCNC | G-code sender | Hobby CNC |

| GRBL tools | Microcontroller control | Arduino CNC |

| PyCAM | Toolpath generation | CAM processing |

Can You Run Linux CNC for Windows?

Linux CNC for Windows is not officially supported, as LinuxCNC is built on a real-time Linux kernel that Windows does not have.

However, there are ways around it:

Options

- Go for dual boot (Linux + Windows)

- Have a dedicated Linux PC

- Run Linux from a USB boot

- Virtual machines (testing only, not real machines)

When it comes to actual CNC hardware control, always opt for native Linux.

Which Linux Distro is Best for CNC?

Lightweight and stable distros are the most suitable ones as CNC requires consistent timing and low latency.

Suggested:

- Debian (official LinuxCNC build)

- Ubuntu LTS

- Linux Mint

- dedicated LinuxCNC ISO image

Stay away from heavy desktops that consume resources.

CNC Workflow on Linux (Simple Setup)

Here is a real-life example of how a lot of shops operate:

- Design a part in FreeCAD

- Generate toolpath using CAM

- Export G-code

- Load into LinuxCNC

- Start machining

Everything is done on a single Linux system.

No additional licenses are needed. No complicated software.

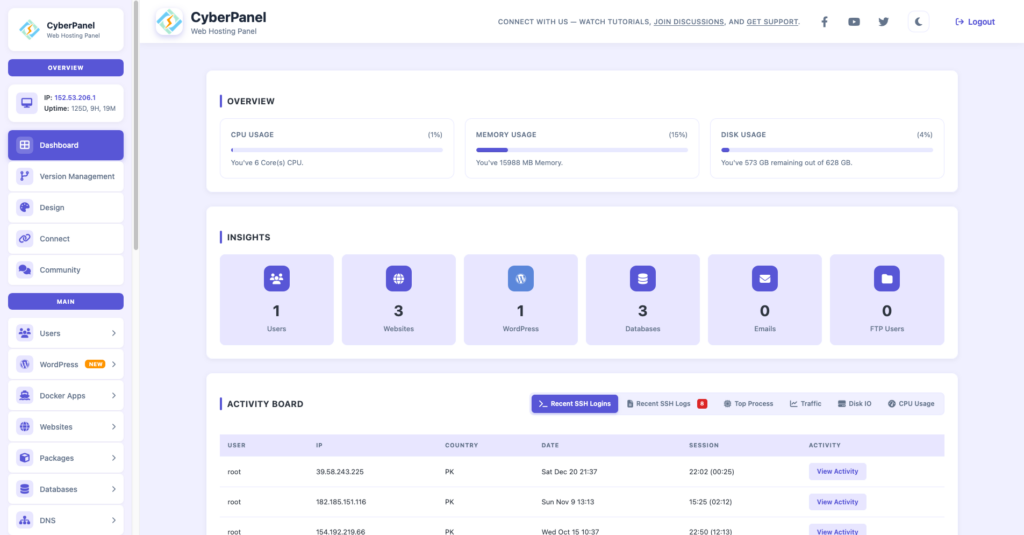

The Role of CyberPanel in CNC Environments

CyberPanel is your free and open-source web hosting control panel.

If you operate:

- CNC training labs

- manufacturing business

- shared CNC setups

- remote monitoring dashboards

CyberPanel comes in handy to manage:

- CNC project files

- G-code backups

- cloud storage

- remote web dashboards

- server-based CAM tools

- automated backups

For example:

You host your CNC job files on a CyberPanel server → access from any Linux CNC machine → start machining.

It centralizes management.

This is extremely useful in workshops with multiple CNC systems

Common Mistakes Made by Beginners

Watch out for these:

- employing Windows for real-time control

- neglecting latency tests

- putting heavy desktop environments

- dropping backups

- using outdated kernels

Whenever a choice comes up, go with stability first, and then, if there is room left, improve the visuals.

Final Words: Should You Use CNC Linux?

If accuracy is your concern, CNC for Linux is undoubtedly the logical decision. Besides, it delivers the stability, speed, and control that are often lacking in Windows.

You get:

- better timing

- fewer crashes

- free software

- professional tools

Put LinuxCNC together with CyberPanel for centralized management, and you have a complete, modern CNC workflow you can proudly call your own.

For high-end machining, going without Linux is no longer a choice; in fact, it has become the standard!

People Also Ask

Does LinuxCNC require internet to work?

No. LinuxCNC runs completely offline. The Internet is only needed for updates or downloading files.

Can I connect multiple CNC machines to one Linux system?

Yes. Advanced setups can control multiple machines, but each may need separate hardware interfaces.

Can I use Raspberry Pi for CNC control?

Possible for light projects, but not recommended for heavy industrial work due to real-time limitations.